Low Pressure Pipe System

Overview

Low pressure pipe systems are similar to standard leaching trench systems in that they distribution wastewater to a series of trenches in the ground. The exception is that low pressure pipe wastewater treatment systems utilize additional technologies.

Low pressure pipe systems utilize pressure to uniformly distribute the water.

Septic Tanks Overview

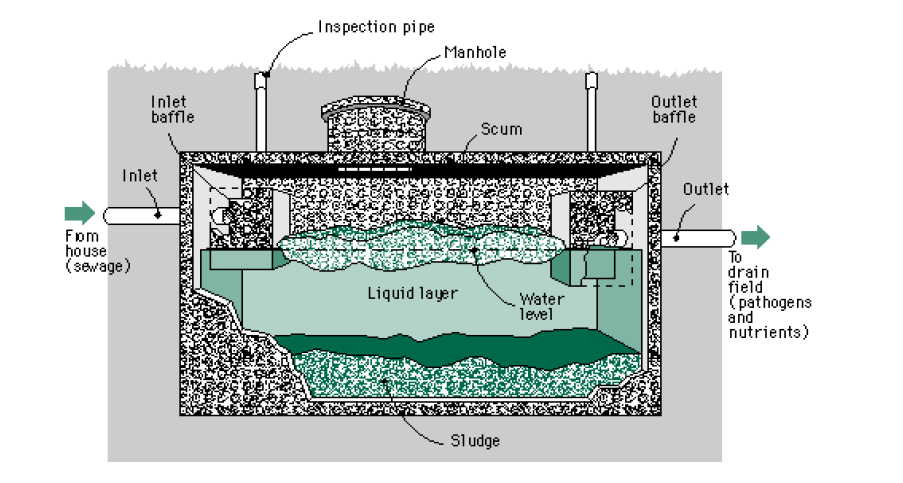

The function of septic tanks in septic systems are to hold back the solid wastes and move on the wastewater. These are normally concrete tanks in the ground which may or may not contain separated compartments. Septic tanks are often crucial part in a septic design. Septic system designs often site septic tanks based first on the local concrete manufacturer. Often times, the capacity of the septic tank sited is dependent on which manufacturer is used. Some manufacturers have longer wait times to manufacturer specific septic tank capacities.

Some septic tanks are made of alternate materials other than concrete, including polyethylene or fiberglass. Some benefits to utilizing these alternate materials is that they are lightweight and can be carried easier with a chain and a small excavator machine. Some septic tanks are so lightweight they can be lifted with several people.

The water from septic tanks is sometimes called septic effluent. The term septic itself means without oxygen and septic effluent is composed mostly of bacteria and human feces. It is a highly contaminated liquid and human contact is dangerous. Septic tank effluent contains particles of sewage of size 1/16 to 3/16 inch in diameter. The waste strength is measure in Biological Oxygen Demand or BOD.

The function of septic tanks in septic systems are to hold back the solid wastes and move on the wastewater.

Some additional technologies are:

Pressure Distribution

Pressure Distribution is not a new concept. It has been used in other states for decades to alleviate the problem of discharging wastewater into clayey soils. The main idea is to evenly distribute the wastewater load evenly over the entire designed soil absorption area. This is done by pumping the wastewater into a pressurized piping system with holes that literally squirt the water evenly into the designed media.

Pressurized septic treatment systems are often difficult to design. They provide a unique and difficult problem in selecting the properly sized and spaced holes in the pressure piping. Pressure piping are composed of sections of Force Main, Manifold, and one or more Laterals. Force main sections transmit the water from the dose tank to the manifold. The manifold splits the force main to the laterals. The laterals are sections of the pressure network that distribute the water to the soil, whether by trench or elevated sand bed.

Some problems with designing these systems are there are meeting the square footage per application hole rule and also meeting the requirement for less than ten percent flow loss, all while maintaining two ft. per second velocity.

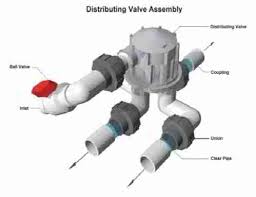

Often times these systems require a valve system to ensure these rules are met for dosing every area uniformly.

Distributing valves come in solenoid or non-mechanical flow actuated types.

Timed-Dosing

Timed-Dosing is a newer technology that has been developed which incorporates timers and electical switches to control a pump and activates it at a specific time. This concept helps prevent overloading sensitive soils and a subsequent blow-out or seepage of wastewater from the soil absorption component.

These types of products have rapidly grown in the variety based on advances in sensors and drop in cost of technology.

Labor of Septic System Installation

Any new installation of a septic system requires planning, installation, and regulatory oversight.

Planners

Regulators

Septic systems, because they can pose health risks when not installed or function properly, by law must have regulatory agencies, commonly your local public health department oversee the design and installation. The regulators often will require a fee through the cost of permit and or site review and multiple visits to the property.

Installation Contractors

Service Contractors

Septic systems require periodic maintenance...some much more than others. A general method of determining the maintenance required is to count up all the mechanical components of a system. The septic tank to Sand Pressure Mound has one mechanical component...the pump system. The Spray Distribution System has 3 mechanical components depending on the type of pretreatment system used...the aeration motor, the ultraviolet light, the pump system. Each mechanical component is wired to an alarm and when it fails, triggers the alarm.