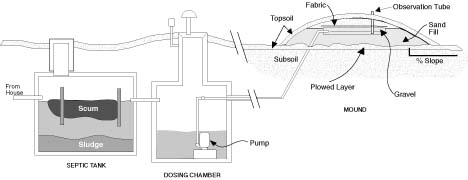

Mounded Leaching System

Overview

The majority of soils in Ohio have been analyzed and classified as having less than adequate sewage treatment capabilities. The reason is these soils are too often clay or a high percentage of clay that allow for little percolation of water. It has been proven through research that overloaded or saturated soils transmit bacteria and viruses extremely longer distances than unsaturated soils. Soil in Ohio can also have too porous media, as in the case of gravelly soils. These soils transmit the bacteria and viruses in soil allowing for little filtration.

System Components

Septic Tanks

Septic Tanks Overview

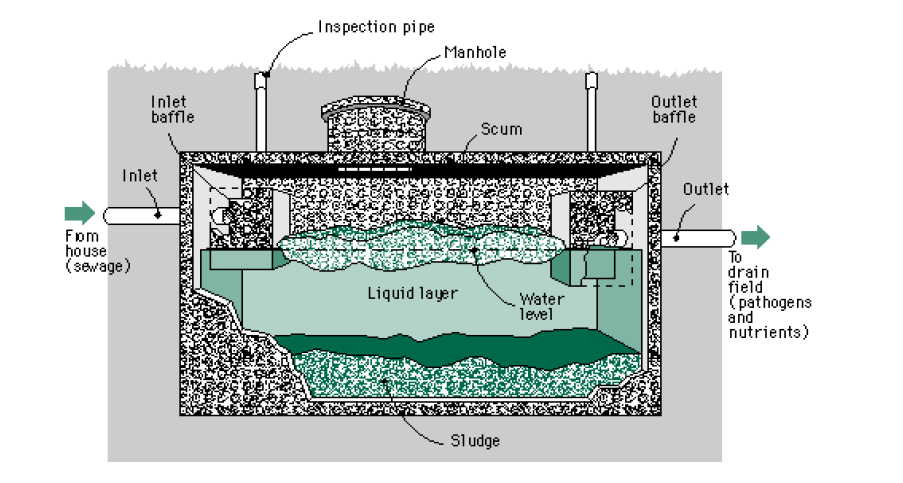

The function of septic tanks in septic systems are to hold back the solid wastes and move on the wastewater. These are normally concrete tanks in the ground which may or may not contain separated compartments. Septic tanks are often crucial part in a septic design. Septic system designs often site septic tanks based first on the local concrete manufacturer. Often times, the capacity of the septic tank sited is dependent on which manufacturer is used. Some manufacturers have longer wait times to manufacturer specific septic tank capacities.

Some septic tanks are made of alternate materials other than concrete, including polyethylene or fiberglass. Some benefits to utilizing these alternate materials is that they are lightweight and can be carried easier with a chain and a small excavator machine. Some septic tanks are so lightweight they can be lifted with several people.

The water from septic tanks is sometimes called septic effluent. The term septic itself means without oxygen and septic effluent is composed mostly of bacteria and human feces. It is a highly contaminated liquid and human contact is dangerous. Septic tank effluent contains particles of sewage of size 1/16 to 3/16 inch in diameter. The waste strength is measure in Biological Oxygen Demand or BOD.

The function of septic tanks in septic systems are to hold back the solid wastes and move on the wastewater.

1. The sewage treatment system installer must notify the system designer and the health department prior to making any changes to the original design. It is crucial that the system be installed exactly to the design plan. If the installation contractor notes any issues with the septic design, the septic installer should contact the designer at that time.

2. If any subsurface drainage is encountered, notify the designer before proceeding.

3. The septic installation contractor should provide an accurate As-Built drawing once installation is complete.

4. The designer and contractor must review the prints before the construction begins.

5. Prior to excavation the registered septic installer shall check all elevations relative to the benchmark to assure proper flow through the system.

6. Sewage treatment areas shall be secured at all times to keep all material and equipment off areas.

7. Construction of the mounded leaching system shall be prohibited during periods when the ground is frozen or saturated with water. This is to prevent smearing of the soil and reducing permeability of the soil.

8. The mounded leaching system is to be built when the soil is dry, so that when scarifying six inches deep, the soil will break up. Be sure to check soil moisture down to at least eight inches deep before scarifying the basal area. Soil should be dry enough to crumble, and not capable of forming a ribbon or wire.

9. Any trees or vegetation within the mound footprint shall be cut as close to ground level as possible and all debris shall be removed. Tree stumps shall remain in place.

10. The mound shall be installed to run parallel to the surface contour of the site to ensure even distribution of sewage effluent.

11. Excavation equipment should be located on the upslope side of the mound to prevent compaction of the downslope flow of water

12. Before scarifying the basal area of the mounded leaching system, trench and layout the force main from the pump chamber to the mound as shown in the attached plans. Cut and cap the force main at the mound an mark its location. Backfill around the force main to prevent seepage back through the trench.

13. The entire footprint of the mound shall be scarified six to eight inches in depth, creating an effective sand to soil interface for the mounded leaching system.

14. After scarifying, immediately place the required depth of approved concrete sand (ASTM C33) over the treatment area to prevent compaction and protect the soil.

15. Prepare the lateral piping, drilling the holes with a sharp drill bit and removing any small burrs.

16. Install the laterals as directed in the septic design plan. It is crucial to follow the septic design plan accurately because the pump is sized based on the number of holes, spacing, and orifice diameter. The system must have the designed pressure in order to function as a sand pressure mound sewage treatment system.

17. Inspection ports shall be installed per plan specifications. The laterals should be sleeved with a four inch perforated pipe.

18. Lateral up-turns shall consist of either a sweeping 90 degree elbow or two 45 degree fittings with a threaded female adapter and watertight cap.

19. Pictures shall be taken of all mound system components before covering with topsoil and at all stages.

20. Two inches of straw or a geotextile fabric must be placed over the distribution area. A minimum of six inches of settled topsoil is required over the entire mound.

Additional Technologies Used in Mounds

Pressure Distribution

Pressure Distribution is not a new concept. It has been used in other states for decades to alleviate the problem of discharging wastewater into clayey soils. The main idea is to evenly distribute the wastewater load evenly over the entire designed soil absorption area. This is done by pumping the wastewater into a pressurized piping system with holes that literally squirt the water evenly into the designed media.

Pressurized septic treatment systems are often difficult to design. They provide a unique and difficult problem in selecting the properly sized and spaced holes in the pressure piping. Pressure piping are composed of sections of Force Main, Manifold, and one or more Laterals. Force main sections transmit the water from the dose tank to the manifold. The manifold splits the force main to the laterals. The laterals are sections of the pressure network that distribute the water to the soil, whether by trench or elevated sand bed.

Some problems with designing these systems are there are meeting the square footage per application hole rule and also meeting the requirement for less than ten percent flow loss, all while maintaining two ft. per second velocity.

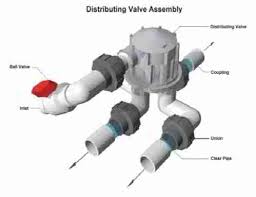

Often times these systems require a valve system to ensure these rules are met for dosing every area uniformly.

Distributing valves come in solenoid or non-mechanical flow actuated types.

Timed-Dosing

Timed-Dosing is a newer technology that has been developed which incorporates timers and electical switches to control a pump and activates it at a specific time. This concept helps prevent overloading sensitive soils and a subsequent blow-out or seepage of wastewater from the soil absorption component.

These types of products have rapidly grown in the variety based on advances in sensors and drop in cost of technology.

Labor of Septic System Installation

Any new installation of a septic system requires planning, installation, and regulatory oversight.

Planners

Regulators

Septic systems, because they can pose health risks when not installed or function properly, by law must have regulatory agencies, commonly your local public health department oversee the design and installation. The regulators often will require a fee through the cost of permit and or site review and multiple visits to the property.

Installation Contractors

Service Contractors

Septic systems require periodic maintenance...some much more than others. A general method of determining the maintenance required is to count up all the mechanical components of a system. The septic tank to Sand Pressure Mound has one mechanical component...the pump system. The Spray Distribution System has 3 mechanical components depending on the type of pretreatment system used...the aeration motor, the ultraviolet light, the pump system. Each mechanical component is wired to an alarm and when it fails, triggers the alarm.