Spray Distribution Systems

How this system works

Spray distribution was established as a method of distributing wastewater first in agricultural applications and settings. Residential wastewater spray distribution has gained some popularity recently due to its allowance as a non-discharging system or onsite treatment system.

A spray distribution works by first treating the wastewater to a high level producing safe disinfected, although still non-potable water. From there the water is pumped to one or more spray heads. There is an average spray radius of approximately 30 ft.

Septic Tanks Overview

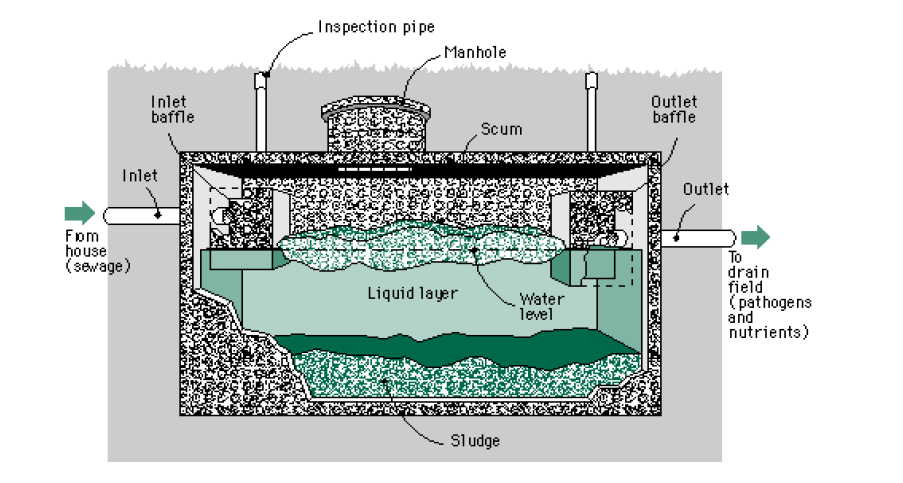

The function of septic tanks in septic systems are to hold back the solid wastes and move on the wastewater. These are normally concrete tanks in the ground which may or may not contain separated compartments. Septic tanks are often crucial part in a septic design. Septic system designs often site septic tanks based first on the local concrete manufacturer. Often times, the capacity of the septic tank sited is dependent on which manufacturer is used. Some manufacturers have longer wait times to manufacturer specific septic tank capacities.

Some septic tanks are made of alternate materials other than concrete, including polyethylene or fiberglass. Some benefits to utilizing these alternate materials is that they are lightweight and can be carried easier with a chain and a small excavator machine. Some septic tanks are so lightweight they can be lifted with several people.

The water from septic tanks is sometimes called septic effluent. The term septic itself means without oxygen and septic effluent is composed mostly of bacteria and human feces. It is a highly contaminated liquid and human contact is dangerous. Septic tank effluent contains particles of sewage of size 1/16 to 3/16 inch in diameter. The waste strength is measure in Biological Oxygen Demand or BOD.

The function of septic tanks in septic systems are to hold back the solid wastes and move on the wastewater.

Secondary Treatment

many advanced treatment systems are one tank with multiple chambers inside the tank. the secondary treatment compartment usually utilizes aeration, filtration, or a combination of both. the product of secondary treatment is usually a wastewater of significantly less polluted than primary wastewater

spray systems require advanced treatment units

spray systems require advanced treatment units

Learn more about Advanced Treatment Units (ATUs)

Tertiary Treatment

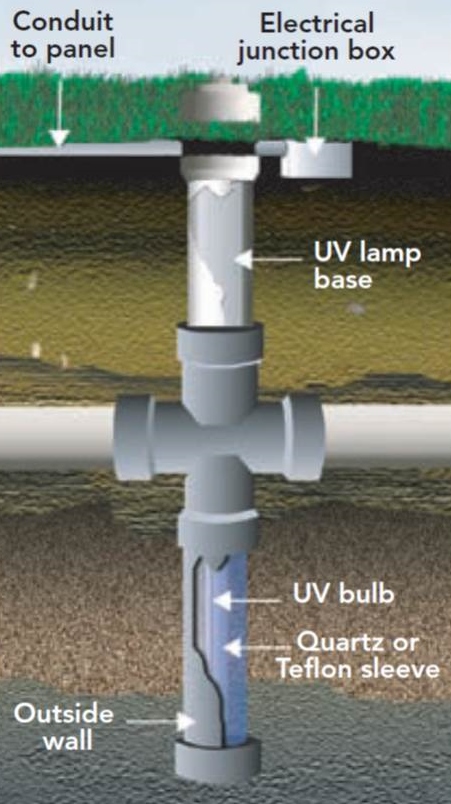

tertiary treatment can be considered the methods to treat the wastewater or secondary effluent to a higher level. this is most often accomplished with disinfection with exposure to ultraviolet light or chemicals. bacteria and viruses cannot live and replicate when introduced to ultraviolet light which destroys their DNA. chemical disinfection works by disrupting the cell walls of bacteria and viruses. Spray systems must have the water disinfected prior to distributing the water via spray heads. water moves from the disinfection unit to another tank. this tank is commonly called the dose tank. the dose tank is the tank that holds the treated water and the centrifigal pump. the pump delivers the water to the spray heads at specific times of the day which is usually controlled by a control panel.

Discharging wastewater from an aeration tank or filter in many areas is not considered acceptable enough or may pose a public health risk due to the presence of high amounts of bacteria or viruses. These are living or reproducing entities which are able to cause disease in animals.

In order to combat the spread of diseases through the transmission of bacteria and viruses, the wastewater discharged from any system should be disinfected. Disinfection often occurs in two different ways for residential wastewater treatment:

Disinfection is part of the entire wastewater treatment package. Disinfection of wastewater really can only occur when the wastewater has mostly been treated. This means the water has been significantly filtered and most of the large solid waste has been removed. Therefore, the effectiveness of any disinfection process depends largely on the different characteristics of the wasetwater, the intensity of the disinfection, and the amount of time the water is exposed to the disinfection process.

Ultraviolet Light

The most effective wavelength of light to inactivate bacteria or viruses is the range of 250-270 nanometers. This is a form of energy radiation which damages the bacteria or virus DNA, or the information of how to copy the organism. The great thing about UV disinfection of residential wastewater is that there is no residual pollutants as is the case of chemical disinfection methods.

Large-scale wastewater UV disinfection

Large-scale wastewater UV disinfection

Residential-scale wastewater UV disinfection

Residential-scale wastewater UV disinfection

Maintenance

UV lights maintenance is required usually every six months and involves removing the bulb from the housing pipe and wiping the outer sleeve to ensure the UV light is unhindered to the wastewater.

Chemical Disinfection

The first form of disinfection of wastewater was through the use of chemicals. The most commonly used chemical for wastewater disinfection is chlorine in the form of liquid or tablets.

Chlorine Tablets

Chlorine Tablets

Chlorine Disinfection Maintenance

Chlorine Disinfection Maintenance

Maintenance

Chlorine disinfection can be a high maintenance and poor performance method for disinfection. Often tablet feeders are can become jammed or tablets may dissolve to quickly in peak flow and result in poor contact time leading to ineffective treatment

Spray Head Units

There are a few companies on the market creating spray unit, spray system packages. Here are the known spray head units on the market.

Norweco Spray Head Unit -- Single Nozzle Head

Wastewater Solutions Spray Head Unit -- Double Nozzle Head

Custom Spray Units -- Single Nozzle Head

There is nothing stopping any company from creating their own custom spray units. To create a spray unit you need to consider many common problems, for example how the spray head opens from the unit, a poor design can cause issues in cold weather

Different residential recycled water spray heads on the market:

Impact Spray Heads - Rain Bird

Rotor Spray Heads - K-Rain

If you don't see your spray head on our site as an option, please contact us and we can add your product details

Spray Head Nozzles

Spray heads have nozzles which can be interchangable. The different nozzles vary in the following ways:

- -Flow in gallons per minute

- -Pressure required in Pounds per Square Inch

- -Throw radius

When selecting nozzles, some things to consider are:

- -Are you meeting the required area. NewSeptic ensures this by calculating this and only allow you to select configurations which meet the required area

- -Do your selected spray heads have a flow which will allows the system to deliver a dose within a reasonable time frame

Back to Back Spray Heads

Back to Back Spray Heads

Spray Head During Deep Freeze

Spray Head During Deep Freeze

Pattern Distribution

Pattern Distribution

Spray Head Closure

Spray Head Closure

Benefits of Spray Systems

Spray distribution for residential wastewater treatment has benefits to traditional systems, including:

Wooded Lots

Some lots, when being developed in areas required onsite wastewater treatment, have limited space which can be utilized for onsite treatment. Wooded areas pose many problems for onsite wastewater treatment. There are added costs for deforesting the area, the lot may loose aesthetic qualities, and some system types do not work as effectively in wooded areas.

Spray heads can be installed areas of at least 5 ft. of distance between the head and the tree. Utilizing spray distribution may allow a residential lot to maintain existing wooded areas.

NPDES treatment unit with timed-dosing

NPDES treatment unit with timed-dosing

recently installed NPDES

recently installed NPDES

Snowy spray operation

Snowy spray operation

Large Volume Distribution

Potentially large volumes of water need to be distributed to soil for onsite treatment. Spray distribution allows significant amounts of water to be discharge to an area designated. Since the water is not distributed into the soil like as in standard leaching trenches or mound systems, there are no issues with potential blow outs or leaking components, which can sometimes happen when soils are overloaded with too much water.